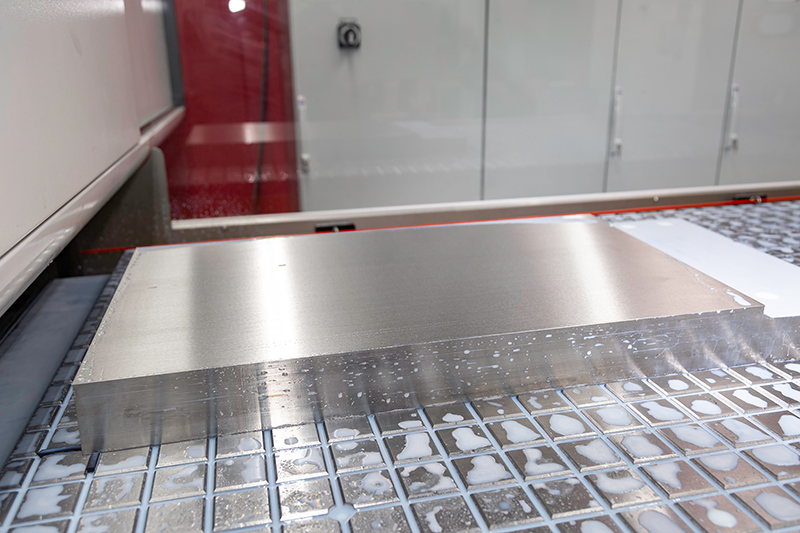

The use of long and wide plate material, particularly in the aerospace sector, brings with it its own set of issues, namely the consistency of the flatness and thickness of the material. While it is possible to grind these sheets using stone abrasives or to mill them, to bring them within specification, wide belt abrasives add a new dimension to the process.

When approached by suppliers of sheet material, particularly titanium and other exotics such as zirconium and molybdenum, Timesavers took on the challenge, looking at the pros and cons of the existing techniques and developing its 81 Series wide belt reciprocating table abrasive machine that delivers considerable productivity gains and cost savings.

!function(e,t,n,c,r,a,i){e.Newsletter2GoTrackingObject=r,e[r]=e[r]||function(){(e[r].q=e[r].q||[]).push(arguments)},e[r].l=1*new Date,a=t.createElement(n),i=t.getElementsByTagName(n)[0],a.async=1,a.src=c,i.parentNode.insertBefore(a,i)}(window,document,"script","https://static.newsletter2go.com/utils.js","n2g");var config = {"container": {"type": "div","class": "","style": ""},"row": {"type": "div","class": "","style": "margin-top: 15px;"},"columnLeft": {"type": "div","class": "","style": ""},"columnRight": {"type": "div","class": "","style": ""},"label": {"type": "label","class": "","style": ""}};n2g('create', 't5up6a9j-uwzoraoj-lbg');n2g('subscribe:createForm', config);